Howard DGA-3 "Pete" - Build Photos

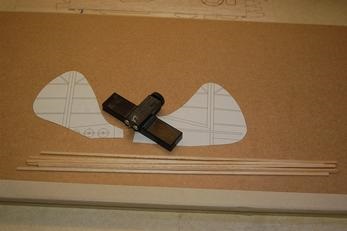

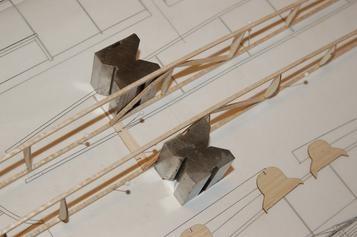

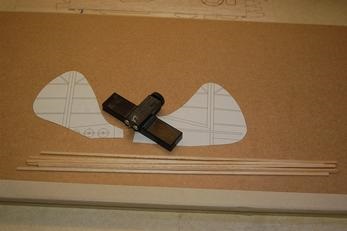

1. Stripping tool and foam forms for building the laminated outlines of the tail group.

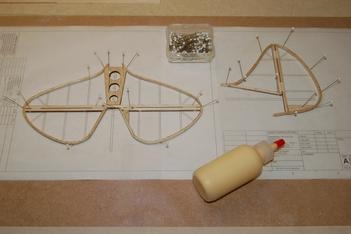

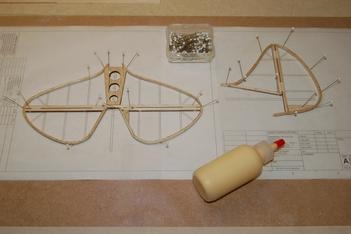

2. Laminations wrapped around the forms and pinned into place while the glue dries.

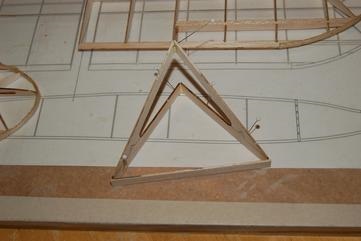

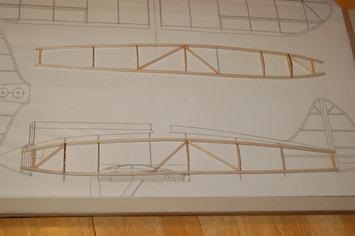

3. Laminated outlines filled with the tail framework.

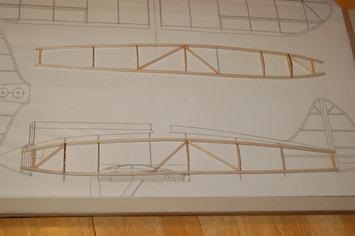

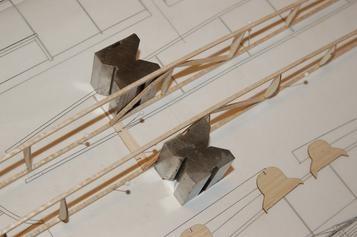

4. Left and right handed side panels built over the plan.

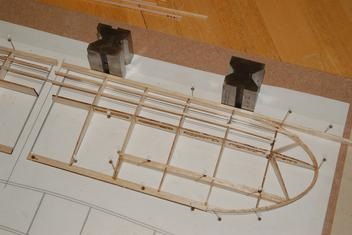

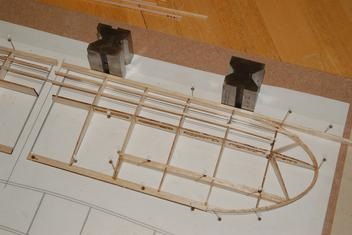

5. Side panels squared up and joined with the lower formers.

6. Top formers going into place.

- Background

- Build photos

- Finished photos

- Videos (coming soon)

- Article - Model Aviation

- RC Groups build thread

- Order a Shortkit from Manzano Laserworks

7. Stringers and sheeting of the nose and rear turtledeck complete.

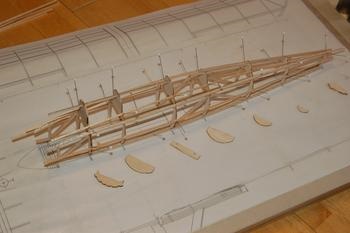

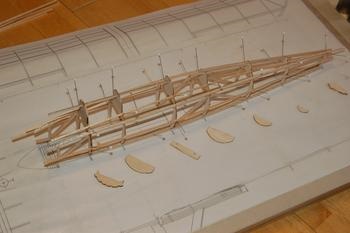

8. Wings going together.

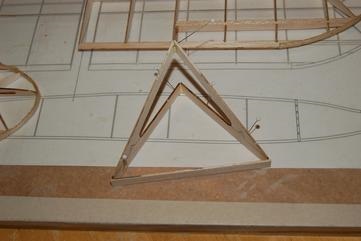

9. Spindly Pete landing gear--the bracing wire is a must-have on this model.

10. Soft balsa spinner turned on a drill.

11. Japanese tissue doped with water-based polyurethane.

Howard DGA-3 "Pete" - Build Photos

1. Stripping tool and foam forms for building the laminated outlines of the tail group.

2. Laminations wrapped around the forms and pinned into place while the glue dries.

3. Laminated outlines filled with the tail framework.

4. Left and right handed side panels built over the plan.

5. Side panels squared up and joined with the lower formers.

6. Top formers going into place.

7. Stringers and sheeting of the nose and rear turtledeck complete.

8. Wings going together.

9. Spindly Pete landing gear--the bracing wire is a must-have on this model.

10. Soft balsa spinner turned on a drill.

11. Japanese tissue doped with water-based polyurethane.